With our plants for the thermal treatment of sewage sludge, municipalities and utilities play an active role in protecting the environment and driving the energy transition – efficiently, in compliance with legislation and sustainably.

All advantages at a glance:

The combustion flue gases are cleaned in several stages. They are odourless and reliably comply with the strict limits of the "Ordinance on the Implementation of the Federal Immission Control Act (BImSchV)".

This type of sewage sludge treatment plant is actively contributing to environmental protection in a number of places and has proven itself over many years, for example in the immediate vicinity of a residential area in Zurich.

Experience, efficiency and tailor-made solutions

KMT GmbH stands for in-depth know-how and long-standing experience in the thermal treatment of sewage sludge. With a team of over 40 experts, we have successfully implemented numerous projects and proven our technological expertise.

Our lean organisation makes for prompt decision-making and efficient project handling. In close cooperation with experienced partners – some of which are members of the MARTIN group – we deliver cost-effective solutions tailored to suit individual requirements that have frequently proven their worth in practice.

We have a clear goal in mind: to harness reliable plant technology for the benefit of a clean and sustainable future.

KMT engineers and implements plants featuring sophisticated process engineering equipment designed to treat sewage sludge in an environmentally friendly manner. The focus is on recovering phosphorus – a vital and rare raw material. We deliver solutions that ensure legally compliant, cost-efficient and sustainable implementation in the spirit of the circular economy.

|

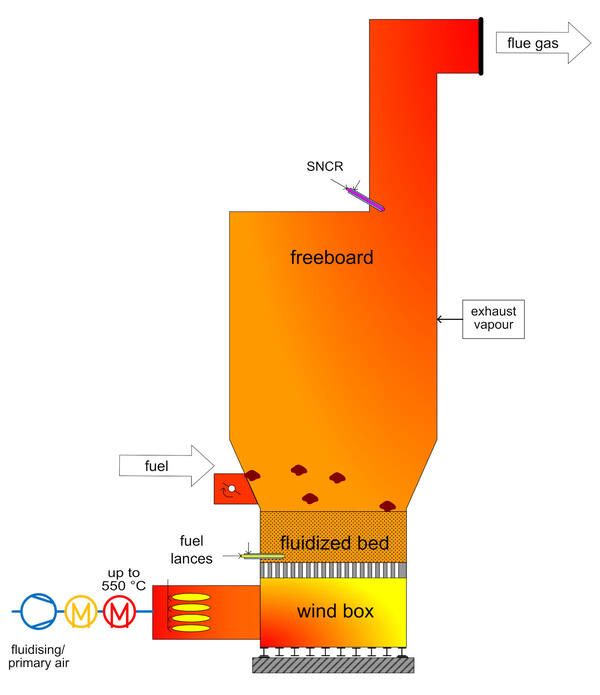

Our plants are based on the proven stationary KMT fluidized-bed technology and ensure the efficient thermal treatment of low-calorific fuels such as sewage sludge – normally without additional fuels. Since the 1990s, our experienced team has been contributing extensive operational experience from various applications involving fluidized-bed systems to deliver sophisticated, reliable solutions. The core component of the system is the KMT fluidized-bed furnace, designed for seamless integration into the overall plant. High plant availability, a high degree of automation, as well as energy and operating media efficiency, are key features of our systems, which always comply with applicable environmental standards. The KMT fluidized-bed incinerator offers flexible configurations – with or without staged combustion air supply – to accommodate the wide range of fuel properties of sewage sludge. The combination of a staged air supply with secondary air and a post-combustion chamber positioned on top makes for particularly stable combustion with low emission levels, even under demanding operating conditions. |

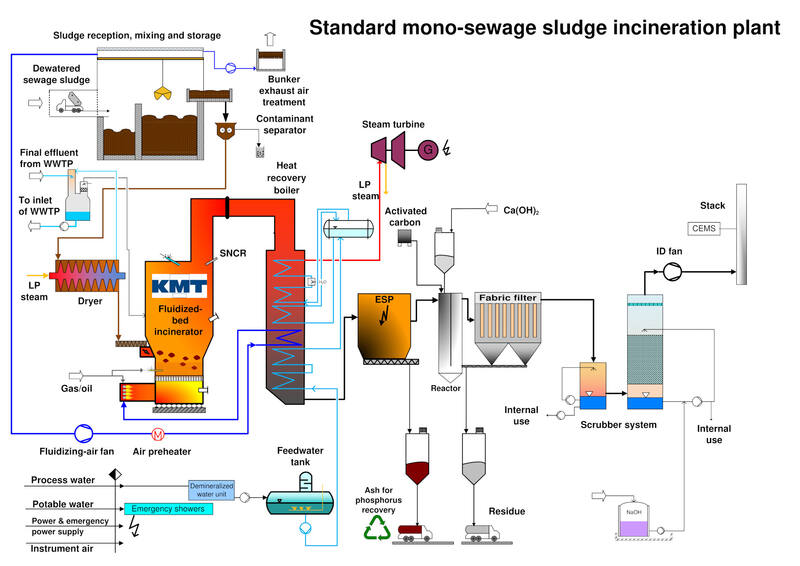

Figure 1: process flow diagram of a typical KMT sewage sludge treatment plant, equipped with a fluidized-bed furnace

Cost-efficient and environmentally friendly sewage sludge treatment requires far more than just a high-performance fluidized-bed furnace. The key factor is the optimal interaction of all plant components – from sludge transport to thermal pre-drying, and from heat recovery in the steam generator to flue gas cleaning. In our plants, over 80 % of the thermal energy contained in the sewage sludge can be used for process purposes. The thermal energy recovered is not only harnessed to dry the sludge and preheat the combustion air, but can also be used to generate electricity or to feed process and district heating networks.

Careful engineering of the flue gas cleaning system is a key element for achieving low emission levels and cost-efficient operation. To that end, we take into account the specific properties of sewage sludge – in particular its sometimes high sulphur and mercury contents. In addition to process engineering, the layout planning and site-specific conditions are also crucial for the design of a plant. In our experience, only a holistic design approach can guarantee operational reliability, efficiency and regulatory compliance of the system in the long-term.

Be it individual components, subsystems or turnkey solutions, KMT always develops concepts in close consultation with the customer, keeping in mind the specific requirements on site. We provide solutions suitable for new plants ("greenfield"), and for integration into existing infrastructures ("brownfield"). Thanks to decades of experience and interdisciplinary know-how, our customers can rest assured that they will find competent contacts at KMT for all project-related tasks – from the initial idea to the ready-to-operate plant.

Your future at KMT – working at two attractive locations

Are you looking for a job where your ideas really have an impact?

We are looking for people who would like to shape the future together with us.

At KMT, you will be part of an innovative team that uses state-of-the-art technology to take the thermal treatment of sewage sludge to a new level – delivering environmentally friendly, sustainable and pioneering solutions. With us, you can unlock your full potential, assume responsibility and actively collaborate on projects that make a difference worldwide. We will nurture your strengths, giving you the benefit of further training, an open working environment and flexible working hours.

Start your career at KMT and join a dedicated team working together towards a clean and sustainable future. Your energy, expertise and commitment are exactly what we are looking for.

At KMT you have got the choice: our teams work at two attractive locations, each with its own unique advantages.

| Butzbach near Frankfurt – an innovative working environment close to nature | Munich – a vibrant metropolis with an inspiring atmosphere | |

|

|

|

| Our Butzbach office, located just half an hour from Frankfurt, combines modern facilities with quiet, natural surroundings. You will enjoy the benefits of a relaxed work-life balance, affordable costs of living and short commuting times. Butzbach is perfect for anyone who appreciates a focused working environment and a high quality of life. | Situated in the heart of Munich, the office in Leopoldstraße not only offers you a central location with excellent transport connections, but also the diversity and dynamism of a cosmopolitan city. Here you will find a creative working environment close to cultural venues, leisure activities and restaurants, as well as to MARTIN GmbH, KMT's parent company. Munich is ideal for anyone who would like to enjoy an urban lifestyle style while feeling the pulse of an innovative technology sector. |

Note:

KMT is part of the MARTIN GmbH group. All applications are therefore processed by MARTIN GmbH.The following link will take you directly to the current vacancies – including those at KMT.